Control mode of servo electric cylinder

2023-03-17(67) Views

1. Torque control: The torque control mode is to set the output torque of the motor shaft through the input of the external analog or direct address assignment. The specific performance is as follows: for example, if 10V corresponds to 5Nm, when the external analog is set to 5V, the output of the motor shaft will be 2.5Nm: if the load of the motor shaft is lower than 2.5Nm, the motor will turn forward. The motor does not rotate when the external load is equal to 2.5Nm, and reverses when the external load is greater than 2.5Nm (usually generated when there is a gravity load). The torque can be changed by immediately changing the setting of the analog quantity, and the corresponding address value can also be changed by means of communication. It is mainly used in winding and unwinding devices that have strict requirements on the force of the material, such as wire device or fiber pulling equipment. The setting of torque should be changed at any time according to the change of winding radius to ensure that the force of the material will not change with the change of winding radius.

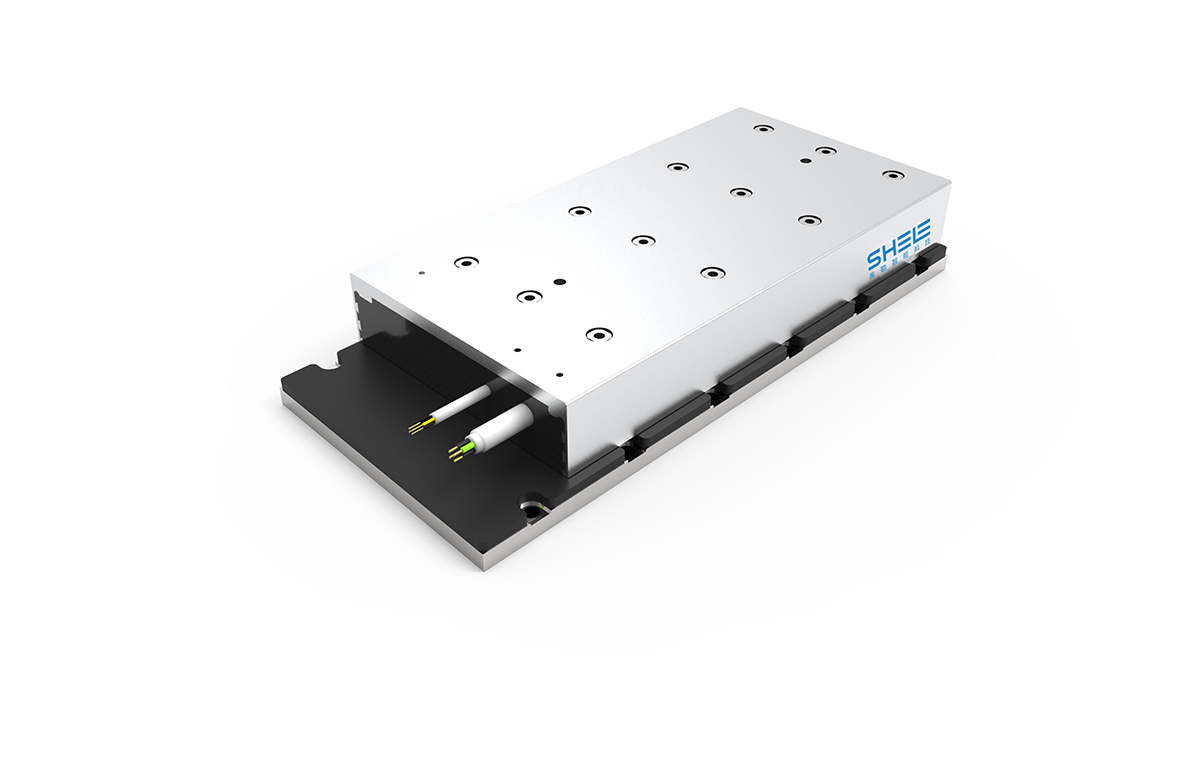

2, position control: position control mode is generally through the external input pulse frequency to determine the size of the rotation speed, through the number of pulses to determine the rotation Angle, also some servo can be directly through the communication mode of speed and displacement assignment. Because the position mode can have a very strict control of speed and position, so it is generally used in positioning devices. Applications such as CNC machine tools, printing machinery and so on.

3, speed mode: through the analog input or pulse frequency can be carried out rotation speed control, in the upper control device of the outer ring PID control speed mode can also be positioned, but must be the motor position signal or direct load position signal to the upper feedback for calculation. The position mode also supports the direct load outer ring to detect the position signal. In this case, the encoder at the motor shaft end only detects the motor speed, and the position signal is provided by the direct detection device at the final load end. The advantage of this mode is that the error in the intermediate transmission process can be reduced and the positioning accuracy of the whole system can be increased.

4, talk about 3 rings, servo is generally three rings control, the so-called three rings is three closed-loop negative feedback PID regulation system. The innermost PID ring is the current ring, which is completely carried out inside the servo driver. The Hall device detects the output current of each phase of the driver to the motor, and gives negative feedback to the setting of the current for PID regulation, so as to achieve the output current as close to equal to the set current as possible. The current ring is to control the motor torque, so the operation of the driver in the torque mode is minimal. Dynamic response is the fastest. The second ring is the speed ring, which is adjusted by negative feedback PID through the signal of the motor encoder detected. The PID output in the ring is directly the setting of the current ring, so the speed ring control includes the speed ring and the current ring, in other words, any mode must use the current ring, the current ring is the root of the control. At the same time of speed and position control, current (torque) control is also carried out in the system to achieve the corresponding control of speed and position.

The third ring is the position ring, which is the outermost ring and can be built between the driver and the motor encoder or between the external controller and the motor encoder or the final load, depending on the situation. Since the internal output of the position control ring is the setting of the speed ring, the system performs the operation of all three rings in the position control mode, and at this time the system has the largest amount of computation and the slowest dynamic response speed.

Recommendations

-

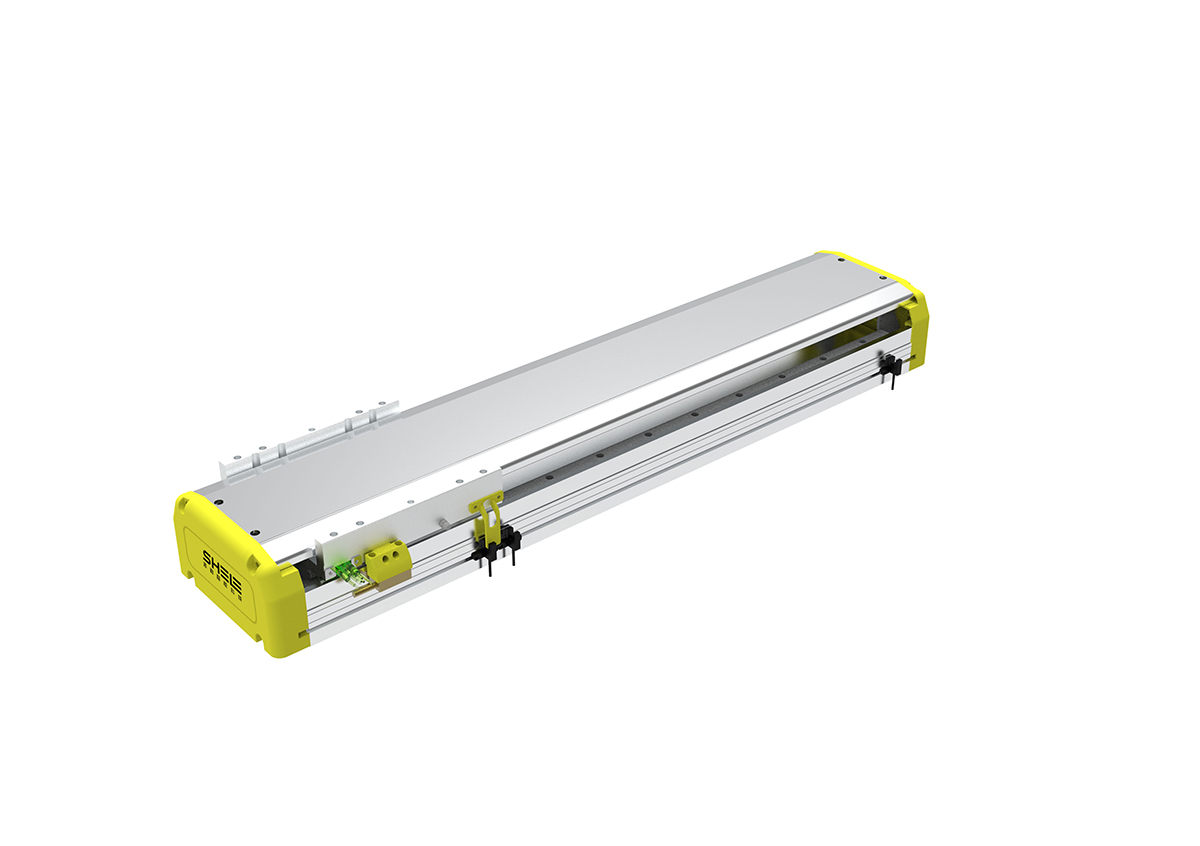

The main causes and solutions of electric module noise

Linear module is also called manipulator, modern military fi...

-

What are the advantages of linear modules?

Linear module can complete the linear movement of load throu...

-

Control mode of servo electric cylinder

1. Torque control: The torque control mode is to set the out...

-

What is the difference between belt type slider and screw type slider?

Belt type slide and screw type slide are the two most common...

-

How to prevent electromagnetic interference of electric push rod?

At present, with the use of more and more electric push rod,...

Menu

Menu Language

Language

0512-65912006

0512-65912006